pagani zonda c12 s

Soft and aggressive, elegant and original, classic and with an eye to the future. This is Zonda C12 S, synonym of exclusiveness and privilege.

The design of the Zonda C12 S, the result of Horacio Pagani’s creative ability, is the maximum expression of aesthetic, aerodynamic and ergonomic research generating strong emotions.

The spirit of improvement of the Zonda C12 S 7.3 is based on a simple concept that we want to defend and exalt: the stubborn rigour in the search for perfection and originality. The car has soft and clean lines, optimized internal and external air intakes and the special pointed “nose”, which was already foreseen in the early sketches examined in 1988 by Juan Manuel Fangio.

The aerodynamic pressure centre is positioned even further back thanks to the displacement of the original dual spoiler, complete with two flaps on the engine bonnet. The overall structure ensures a high aerodynamic efficiency for the entire car, contributing to the considerable aesthetic impact.

The rear lights, the network of air outlets and the round housing of the four exhaust terminals create an original and unique geometry: a real “trademark” for the Zonda C12 S. Today, more than ever, Zonda C12 S represents fascination, power, and aggressiveness in a pure form.

The extremely lightweight bonnets, under which the carbon “speaks”, house the mechanics, exposed like a work of art in a central position and supported by two small Cr-Mo tubular frames.

Engine

The new 7.3 engine with titanium connecting rods is equipped now with a specifically designed and entirely handmade air intake system; this new feature enwraps the engine and gives the unit an even more impressive overall appearance. The air intake positioned in a high-pressure area contributes to enhance the efficiency of the 7.3 engine that with a maximum power output of 555 bhp and confirms the excellent work done by the Mercedes AMG technicians.

The excellent performance is achieved while complying with the most demanding technological standards; producing a torque figure of 458 lb-ft already at 2,000 rpm which increases up to 554 lb-ft at 4,050 rpm. The redline at 7,000 rpm heightens the aggressive sporting character, which was already a feature of this engine, without overshadowing its flexible and progressive qualities.

The Euro III type approval completes the attractive features of this racing engine and allows the engine to be used normally on standard roads.

The central carbon chassis is produced by implementing aeronautical methods and incorporates the Cr-Mo and composite roll bar.

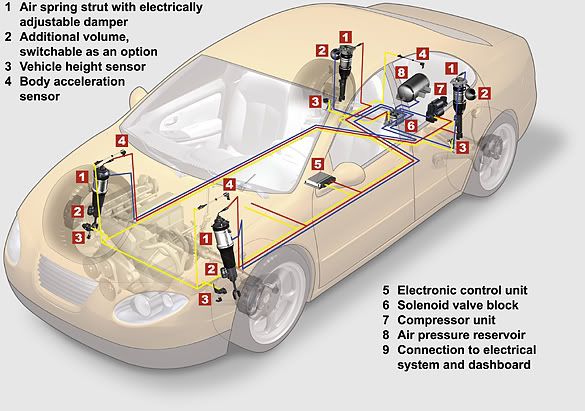

The front sub-frame has a high impact absorbing capacity, ensuring an excellent degree of protection; passive safety is optimum in the event of a crash or rollover. The rear sub-frame is designed to support the load of the mechanics and of the sophisticated aluminium suspensions. In addition, the new Zonda C12 S 7.3 is equipped with ABS, Traction Control, adjustable suspensions with Ohlins shock absorbers, Brembo braking system, with 4 very generously sized self-ventilated discs, 18” OZ Racing alloy wheel rims and specifically designed Michelin Pilot Sport tires. The engineering in the construction of the Zonda is as innovative as its design concept, and is a statement about the philosophy that guides Haracio Pagani and his team: a search for visual and technical perfection in every detail, even the smallest and most insignificant.

The Pagani Automobili company and Modena Design, the partner in this project, hope that they have reached their goal: the final word in the matter is left to the fortunate owners who are the real fans and connoisseurs of this category.

Road Performance

The dynamic characteristics, which can always be exploited in every condition, combine to make the Zonda C12 S a real “object of pleasure”.

The silent running Mercedes engine, the luminous dome roof, the excellent soundproofing and the virtual total absence of vibrations (the result of careful design) offer incredible comfort.

To the real car enthusiast the Zonda C12 S presents itself as a reactive car in every condition, free from roll and pitch effects and with extremely precise steering.

The road holding capacity is good and safe: not only thanks to the excellent suspensions and the very rigid chassis, but also to the high aerodynamic efficiency of the bodywork which offers an overall negative lift equal to 1102 lb at a speed of 186 mph.

The Zonda is capable of being placid and comfortable in normal driving conditions, or becomes a racing car unleashing the “beast” that Zonda harbors inside.

this is one of the pics i got from a recent motor show!

A site For All u Car lovers..........

A site For All u Car lovers..........